Markets served: Medical - Diagnostic hardware, medical electronics and medical imaging devices. Telecommunications PCBTelecommunications - High frequency chip carriers and fiber-optic communication products. Industrial and Commercial PCBIndustrial & Commercial - robotics, consumer electronics and LED lighting applications. Car and Automotive PCBAutomotive - Camera modules, lighting and other automotive electronics...

DuPont™ Pyralux® materials have been the foundation of the flex circuit industry for decades and comprise a broad offering of materials used to make circuitry in a wide variety of applications. These materials enable the design and manufacture of increasingly complex circuits for greater functional capacity and miniaturization.

For furhter information, please feel free to contact us, www.pcbsino.com

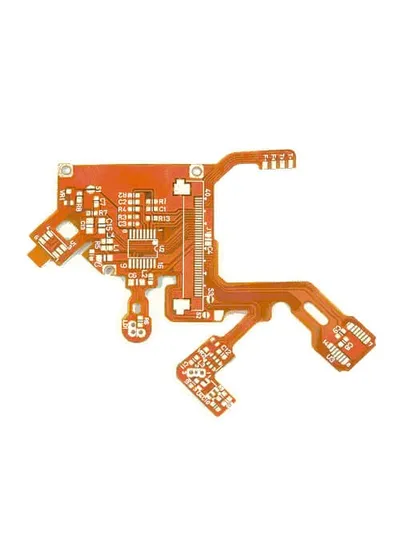

More flexibility, as the "flexible" name meaning. Improved resistance to vibrations and movement; lower mass/weight. Small package size. Smaller thickness;.

These advantages allows the board to bend to its desired applicable shape. Allows for more compact devices. High tensile strength—can be significantly warped/deformed without breakage. High bendiness—up to 360 degrees. Easier to prepare for harsh environments, and these functions are very useful. The use of flexible flat cables (FCC), which can bend without being damaged, and takes up less space than traditional wires Flexible PCB // Flex circuits there are around 10% PCB is Flexible PCB globally.

Below you will find some resources for flex circuit connectors and materials from industry suppliers. Industry Suppliers

Flex Circuit Technology, Panasonic, Dupont, Shengyi Technology Co. Ltd., Aplus, Thinflex, TaiFlex, ITEQ, Ventec International Group, Tatsuta Electronic Materials, Taiyo, 3m, Tesa