Multilayer PCB Prototype Manufacturer China,impedance control HDI

Contract manufacturing of multilayer pcb, blind/buried via,Mass Production

Multilayre PCB, High speed,Shenzhen,China/USA/UK/India/South Africa

multilayer pcb is useful in high-speed application

-

multilayer pcb is used very normal.

The multilayer pcb is mainly used in industry electronic equipment,Like computers and military equipment, especially in the case that need light weight and volume.The multilayer pcb is also useful in high-speed application. The mltilayer pcb can provide more space for the conductor pattern and power.

Multilayer PCB |

|

Multilayer PCB Prototype |

| blind via |

|

Manufacturer China,impedance control HDI |

| HDI PCB |

|

blind/buried via,Mass Production |

Multilayer PCB |

|

blind/buried via,Mass Production |

| HDI PCB |

|

impedance control HDI |

| blind via |

|

Medical equipment aplication |

HDI PCB |

|

impedance control HDI |

| impedance |

|

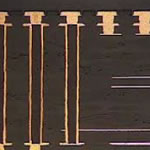

0.1mm Laser drill via |

| Laser drill |

|

Multilayer PCB Fabrication |

Multilayer PCB |

|

Multilayer PCB Fabrication |

| impedance |

|

Multilayer PCB Prototype |

| Laser drill |

|

Carbon/Silver Ink Printing or Gold-plated Surface |

impedance |

|

Multilayer PCB Fabrication |

| Multilayer PCB |

|

Multilayer PCB Prototype |

| Aplication: |

|

Industry control boards |

Benefits of Multilayer PCBs

-

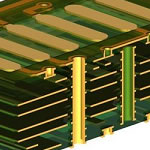

The multilayer pcb is made up by more than two layers which are stacked together with reliable through via or blind via between them. There are at least three conductive layers in one multilayer pcb with two layers outside and the one layer inside the PCB. Due to the complex manufacturing process and lower production , the cost of multilayer pcb is relatively higher.PCBSINO is specialized in multilayer PCB manufacturing for many years.

Benefits of Multilayer PCBs

Benefits of Multilayer PCBs (compared to single or double-sided PCBs)

Higher assembly density

Smaller size (considerable savings on space)

Increased flexibility

Easier incorporation controlled impedance features. EMI shielding through careful placement of power and ground layers.

Reduces the need for interconnection wiring harnesses (reduces overall weight)

multilayer PCB fabrication – lay-up and bond

The outer layers of our multilayer consist of sheets of glass cloth pre-impregnated with uncured epoxy resin (prepreg) and a thin copper foil.

Multilayer PCB

Multilayer PCBs have one or more conductor pattern inside the board, to increase the area available for the wiring. This is achieved by gluing (PP) many double-sided circuit boards together with insulating layers in between.

The number of layers is referred to as the number of separate conductor patterns – usually including the two outer layers. Most boards have between 4 and 8 layers, but PCBs with almost 100 layers can be made.

Since the layers in a PCB are laminated together, it’s very difficult to tell how many there are, but if you inspect the side of the board with magnifier closely you might be able to count them.

Large super computers often contain boards with multilayer PCB.

Applications of Multilayer PCBs

-

Applications of Multilayer PCBs

While the weight and space benefits of multilayer PCBs are especially valuable for Aerospace PCBs, multilayer PCBs are also apply to many critical product. below are a few other the applications using multilayer printed circuit boards:

Computers

File servers

Data storage

Signal transmission

Cell phone transmission

Cell phone repeaters

GPS technology

Industrial controls

Satellite systems

Hand held devices

Test equipment

X-ray equipment

Heart monitors

Cat scan technology

Atomic accelerators

Central fire alarm systems

Fiber optic receptors

Nuclear detection systems

Space probe equipment

Weather analysis

For furhter information, please feel free to contact us, www.pcbsino.com